Diamond geological bits serve as critical tools in geological exploration, playing an irreplaceable role in complex geological conditions due to their unique material properties and manufacturing advantages. Their applications span multiple stages including geological surveys, resource development, and engineering investigations, forming the core support for enhancing operational efficiency and data accuracy.

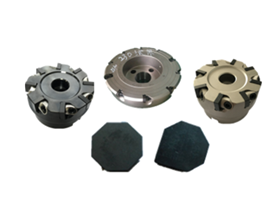

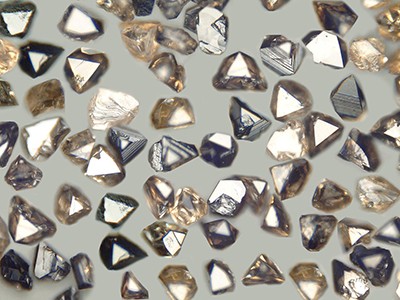

In fundamental geological exploration, the core value of diamond drill bits lies in the drilling process. Their core material, the diamond-coated composite bit (PDC), integrates diamond powder with a cemented carbide matrix through high-temperature, high-pressure processing, forming a composite structure that combines exceptional hardness with impact resistance. This characteristic enables efficient penetration through soft to medium-hard rock formations and even tackles the challenges posed by high-hardness strata. For instance, in metal mineral exploration, these bits rapidly drill through hard formations like granite and quartzite to obtain intact core samples, providing reliable data for ore body localization. In coalfield exploration, their exceptional wear resistance significantly reduces drill bit replacement frequency, markedly increasing daily operational efficiency compared to traditional tools.

Technological advancements have further expanded the application boundaries of diamond geoflaps. New composite flaps, through optimized diamond particle distribution and interface bonding processes, significantly enhance impact resistance and thermal endurance, enabling adaptation to high-temperature formations and complex stress environments. In oil and gas exploration, these advanced blades ensure stable drilling through heterogeneous formations like shale and sandstone, guaranteeing precision in directional and horizontal well construction. Modular design allows flexible adjustment of cutting edge angles and thickness based on formation characteristics: ultra-thin designs reduce drilling resistance in narrow vein exploration, while spherical tooth structures enhance cuttings removal in fractured formations.

In terms of application domains, diamond geologic bits have achieved diversified coverage. Beyond traditional geological surveys, their use is increasingly widespread in emerging fields such as engineering geology exploration, disaster geology monitoring, and geothermal resource development. For instance, during preliminary geological reconnaissance before tunnel excavation, these bits rapidly gather information on forward rock formations, providing data support for optimizing construction plans. In seismic fault studies, their high-precision drilling capability aids in obtaining samples from deep fracture zones, advancing geological structural theories. This cross-domain penetration not only elevates exploration operations' technical standards but also provides crucial support for technological upgrades in related industries.