In the field of glass manufacturing, the efficiency and quality of the mold release process directly determines the product yield and production cost. Hexagonal boron nitride (h-BN) powder, an advanced ceramic material known as “white graphite”, is gradually replacing traditional mold release materials with its unique physicochemical properties, becoming a revolutionary solution for the glass processing industry.

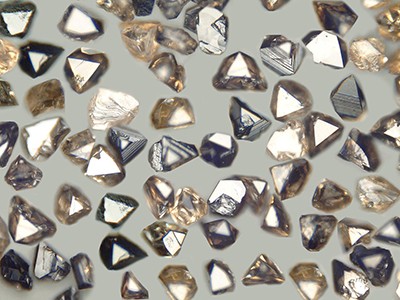

The crystal structure of h-BN is highly similar to that of graphite, with alternating boron and nitrogen atoms forming hexagonal mesh layers, which are bonded by van der Waals forces. This structure gives h-BN an extremely low coefficient of friction and stable lubrication properties even at high temperatures. Experimental data show that in the thermal shock test at 1500°C, h-BN coated molds remain crack-free after many rapid cooling and heating cycles, and its thermal shock resistance far exceeds that of graphite-based mold release agents. What is even more remarkable is that h-BN can still maintain structural stability in an inert atmosphere at 2800°C, a characteristic that makes it perfectly suited for high-temperature molding processes such as optical glass and borosilicate glass.

In addition to its excellent high temperature stability, h-BN excels in chemical stability. It neither reacts with molten glass nor is wetted by molten metals such as iron, copper and aluminum. Practical application data from a glass container manufacturer shows that the service life of the mold has been extended by more than three times with the use of h-BN-based release agent, while the surface defect rate of the glass product has been drastically reduced from 8.7% to 1.2%. This excellent anti-adhesion performance stems from the extremely low surface energy of the h-BN surface, which prevents the glass melt from forming strong chemical bonds during solidification.

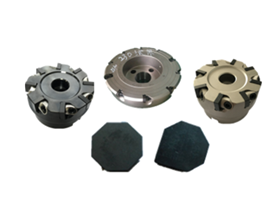

Compared to the traditional graphite emulsion or boron nitride spraying processes that are relied upon for glass mold release, the application of h-BN powder has achieved three major technological breakthroughs. Its aqueous dispersion system can be sprayed, impregnated and other ways to form a film, after drying to form a uniform coating thickness of only 5-10μm. Under the high-speed operation scenario of row-type bottle-making machine, h-BN coating can withstand more than 300 thermal cycle impacts per minute to ensure the stability of continuous production. In addition, h-BN's self-cleaning properties reduce mold cleaning time by 70%, significantly improving the overall efficiency of the production line.

In the field of precision optical glass processing, the advantages of h-BN are even more prominent. While traditional mold release agents tend to leave carbonaceous contaminants on the lens surface, h-BN coatings can achieve a 99.8% removal rate through simple blowing after mold release, meeting the stringent requirements of laser devices for glass surface cleanliness. Tests by an aerospace optics manufacturer showed that the processing pass rate of high-precision aspheric lenses increased from 65% to 92% after the h-BN release process was adopted.

As the global glass products market continues to grow, the demand space for h-BN materials is also expanding. It is predicted that China's hexagonal boron nitride market size will expand at a CAGR of 12% from 2025-2030, of which the contribution of the glass release field is expected to reach 28%. Especially in emerging markets such as new energy automotive glass and microcrystalline glass for 5G communication filters, the demand for h-BN materials is increasing at an annual rate of 35%.

As a leading supplier of h-BN materials, BN(CHINA) Technology's h-BN products are synthesized using advanced continuous calcination equipment, with an annual production capacity of 800 tons. The products have stable performance, strong batch supply capability and outstanding cost advantage. Currently, Nitrogen Boron Technology provides four specifications of h-BN products: PBN700 (purity ≥99.5%), PBN500 (purity >99%), PBN300 (purity >98%), and PBN100 (purity >97%). These four products are available in crystalline particle size between 1-5 μm and powder particle size D50 between 4 μm-20 μm, and have been successfully applied in many industries such as boron nitride ceramics, high-temperature coatings, mold releasing agents, lubricants, thermally conductive fillers, high-temperature insulating materials and so on.