In humanity's quest to explore the cosmos, rocket propulsion systems serve as the “power engines” propelling spacecraft into the stars. However, the inner walls of these propulsion systems face extreme challenges—blistering temperatures, immense pressure, high-velocity gas flow erosion, and chemical corrosion—that traditional materials struggle to withstand. Here, hexagonal boron nitride(h-BN) emerges as a “protective shield” for these critical surfaces, thanks to its unique properties.

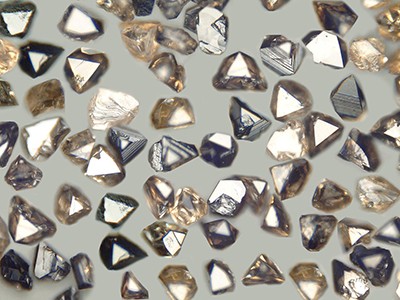

High-Temperature Resistance and Thermal Stability: Confronting the “Flaming Inferno”

Temperatures within a rocket engine combustion chamber can soar above 3000℃. Traditional materials readily soften, melt, or even oxidize and fail under such extreme heat. h-BN, however, demonstrates exceptional high-temperature resistance. With a melting point exceeding 3000℃ (sublimation), it remains stable at 3000℃ in inert gas environments and retains excellent performance at 1000℃ in oxygen-rich conditions. This stems from its unique layered structure, where boron and nitrogen atoms are bound by strong covalent bonds, while interlayer connections rely on van der Waals forces, endowing it with exceptional thermal stability. In solid rocket motors, coating the inner walls with h-BN acts like “fireproof armor,” effectively isolating high-temperature combustion gases from the metal substrate. This prevents thermal stress cracking and significantly extends engine lifespan.

Chemical Inertness and Corrosion Resistance: Defending Against “Corrosion Monsters”

The combustion products of rocket propellants contain complex components, including highly corrosive substances like chlorine and fluorine. These act like “corrosion monsters,” severely eroding metal inner walls. However, h-BN remains unaffected by nearly all molten metals, organic solvents, concentrated acids, dilute acids, and strong alkalis. It reacts only with molten potassium hydroxide or incandescent chlorine gas. In liquid oxygen/kerosene engines, applying a h-BN coating prevents carbon deposits and high-temperature oxidation from kerosene combustion. This keeps the inner walls clean, reduces friction losses, and ensures efficient propulsion system operation.

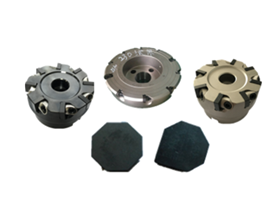

Lubricity and Thermal Shock Resistance: Buffering High-Speed Gas Flow Impact

During rocket engine operation, gas flows at extreme velocities—reaching thousands of meters per second—subjecting inner walls to intense mechanical erosion. The layered structure of h-BN (h-BN) imparts graphite-like lubricity, with a friction coefficient of just 0.15–0.25. This acts like applying “lubricant” to the inner walls, significantly reducing friction wear caused by high-speed gas flows. Simultaneously, its low thermal expansion coefficient and excellent thermal shock resistance prevent cracking during repeated thermal cycling. In ramjet engines, h-BN coatings mitigate thermal stresses caused by sudden temperature changes, preventing wall spalling and ensuring stable propulsion system operation.

Neutron Absorption and Weight Reduction: Achieving Radiation Shielding and Efficiency Enhancement

The boron element in h-BN possesses strong neutron absorption capabilities, making it suitable for radiation shielding in nuclear thermal rocket propulsion systems. Moreover, with a density of only 2.25 g/cm³—approximately one-fourth that of nickel-based high-temperature alloys—it significantly reduces engine weight, increasing spacecraft payload capacity. In deep-space exploration missions, propulsion systems utilizing h-BN composites can lower fuel consumption, extend mission lifespans, and empower humanity to explore the farthest reaches of the cosmos.