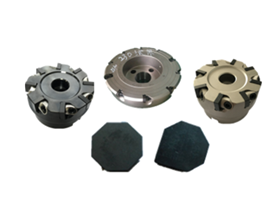

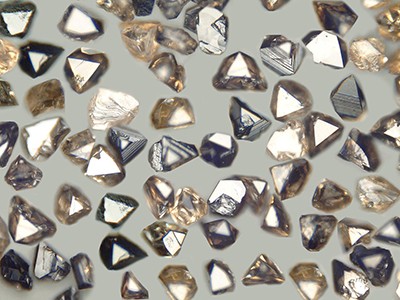

Diamond composite cutting tools, owing to their unique performance advantages, play an irreplaceable role across numerous industrial sectors. Manufactured by sintering synthetic diamond abrasives with metal powders, resin powders, and other binders onto a cemented carbide substrate under high temperature and pressure, these tools combine diamond's exceptional hardness and wear resistance with the strength and impact toughness of cemented carbide. They are truly indispensable for modern precision machining.

In petroleum drilling and geological exploration, it is the key material for drill bit manufacturing. Traditional cemented carbide drill bits suffer rapid wear and reduced drilling efficiency when encountering medium-hard to hard formations. In contrast, diamond-tipped drill bits maintain sharp cutting edges for extended periods due to the high hardness and wear resistance of their polycrystalline diamond surface layer. Their excellent heat resistance significantly boosts drilling speed and extends service life, making them ideal tools for deep and ultra-deep well drilling.

The mechanical processing industry represents another vital application for diamond-coated cutting tools. When machining non-ferrous metals like aluminum, copper, and magnesium alloys, conventional tools often suffer from material adhesion, leading to increased cutting forces and accelerated wear. Diamond-coated tools, with their low friction coefficient and high thermal conductivity, enable high-speed cutting and produce extremely low surface roughness, achieving a mirror-like finish. When machining high-silicon aluminum alloy components like automotive engine pistons and carburetors, they maintain stable cutting performance over extended periods, delivering dimensional accuracy and surface quality far surpassing that of carbide tools.

The machining of composite materials places extremely high demands on cutting tool performance, and diamond-coated composite tools have emerged as the key solution due to their unique advantages. In the machining of carbon fiber-reinforced plastics, traditional tools often cause material delamination and tearing, leading to machining defects. CVD diamond-coated tools deposit nanoscale diamond films onto carbide substrates, preserving the substrate's impact resistance while imparting exceptional hardness and wear resistance. Their use significantly extends tool life and produces burr-free, delamination-free surfaces, meeting aerospace demands for high-precision machining of composite structural components.

Furthermore, diamond composite cutting tools demonstrate exceptional performance in machining brittle materials like ceramics, glass, and cemented carbide. Take zirconia ceramic machining as an example: while conventional tools often suffer edge chipping due to material brittleness, diamond composite tools achieve stable cutting through optimized cutting edge geometry and coating processes. This results in extremely low surface roughness, providing robust technical support for high-end manufacturing in medical ceramics, electronic ceramics, and other fields.

From deep well drilling to precision manufacturing, from aerospace to everyday consumer electronics, diamond-coated cutting tools drive industrial processing toward greater efficiency and precision with their exceptional performance. They have become indispensable “industrial teeth” in modern manufacturing.