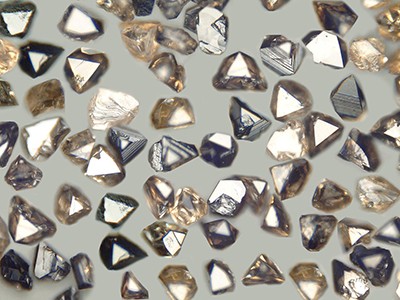

In the field of high-temperature smelting and material preparation, crucibles serve as core containers whose performance directly impacts product purity and quality. Hexagonal boron nitride (h-BN) powder, with its unique properties, is increasingly becoming the preferred material for crucible manufacturing.

Composed of boron and nitrogen elements, hexagonal boron nitride powder exhibits a pure white appearance and a graphite-like layered structure. This structure endows it with numerous outstanding properties. Its high-temperature resistance is exceptionally remarkable, remaining stable in air up to 1200°C and maintaining performance integrity in protected atmospheres even at 2300°C. This characteristic enables it to withstand the high-temperature challenges of processes like metal smelting and purification, ensuring the crucible remains undamaged and unaffected by deformation during prolonged high-temperature operation.

During metal smelting and purification, hexagonal boron nitride crucibles demonstrate unique advantages. They exhibit excellent non-wetting properties toward highly reactive metals such as pure aluminum, magnesium, tin, and their alloys. When molten metal contacts the crucible, no wetting occurs. The molten metal separates completely from the crucible, significantly improving metal recovery rates while effectively preventing impurity contamination, thus ensuring high metal purity. For instance, in the semiconductor industry, when used to hold metal sources like aluminum and gallium in molecular beam epitaxy (MBE) processes, its high-temperature stability and cleanliness provide an ideal environment for semiconductor crystal growth, ensuring consistent semiconductor crystal quality.

Hexagonal boron nitride crucibles also exhibit outstanding chemical stability. They demonstrate excellent resistance to corrosion by acids, alkalis, and glass melts, and neither wet nor react with most molten metals. In the glass processing industry, when used for melting transparent quartz glass or specialty optical glass, it does not chemically react with the molten glass. This enables the production of defect-free, high-purity glass products that meet the stringent quality requirements of high-end optical glass.

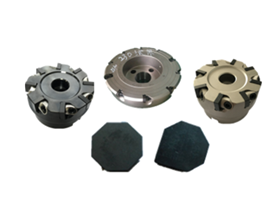

In terms of manufacturing processes, hexagonal boron nitride crucibles are primarily produced through hot-pressing and chemical vapor deposition (CVD). Hot-pressed crucibles are manufactured from h-BN powder under high temperature and pressure, resulting in a dense structure with high mechanical strength capable of withstanding external impacts. Vapor deposition crucibles, on the other hand, are produced by depositing pure h-BN coatings onto substrates like graphite via chemical vapor deposition. These coatings exhibit extremely high purity and porosity-free properties, further enhancing the crucible's performance.

Although hexagonal boron nitride crucibles carry a higher cost than traditional graphite or ceramic alternatives, their advantages in enhancing product purity, yield rates, and process stability drive sustained demand growth across high-tech sectors including aerospace, semiconductors, optoelectronics, and nuclear industries. With continuous advancements in preparation techniques and gradual cost optimization, the application prospects of hexagonal boron nitride powder in crucible manufacturing will expand significantly, positioning it as a key material poised to drive the development of high-end manufacturing.