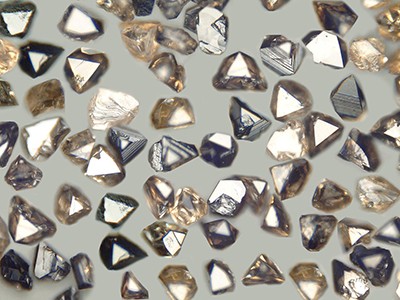

Cubic boron nitride (CBN) abrasives, as an ultra-hard material, exhibit distinct application patterns across various industrial scenarios, where particle size selection directly impacts machining efficiency, surface quality, and tool life. This artificially synthesized material, second only to diamond in hardness, offers superior thermal stability and chemical inertness, making it particularly suitable for precision machining of ferrous metals. Its particle size range typically spans from micrometers to millimeters, with each size catering to specific machining requirements, forming a matching system based on material properties and process objectives.

In precision grinding, fine-grain CBN abrasives dominate. These micron-sized particles are commonly used for finishing high-precision components like automotive engine camshafts and gears. For instance, in automotive manufacturing, camshaft surface roughness must be controlled at extremely low levels. Employing fine-grain CBN grinding wheels with high-speed grinding processes ensures dimensional accuracy while preventing thermal damage like burn marks. Similarly, the tooth surfaces of aerospace gears exhibit extremely high hardness. Form grinding with fine-grained abrasives enables micron-level control with minimal feed rates per pass, ensuring meshing accuracy. In such scenarios, fine-grained CBN enhances surface integrity by reducing the macroscopic dimensions of the cutting edge, though it requires high-rigidity machine tools to mitigate vibration effects.

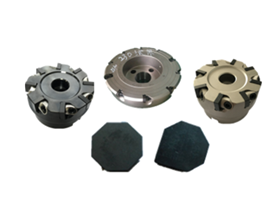

Medium-grain CBN abrasives are more commonly used in semi-finishing operations. In heavy machinery manufacturing, medium-grain abrasives are often employed during the rough grinding stage of large components like rollers and crankshafts. These parts feature high material hardness and substantial machining allowances. Medium-grain abrasives maintain high material removal rates while effectively controlling grinding wheel wear rates. For instance, in steel industry roller restoration, medium-grade CBN grinding wheels remove substantial stock in a single pass while maintaining low surface waviness, providing a stable reference for subsequent finishing operations. This grain size strikes a balance between efficiency and precision, making it an economical choice for heavy-stock removal applications.

Coarse-grained CBN abrasives excel in high-efficiency heavy-cutting applications. During rough machining of cast iron components or slotting processes on quenched steel, coarse-grained abrasives enable substantial material removal per feed. For instance, in manufacturing rail transit vehicle brake discs, coarse-grained CBN grinding wheels achieve significantly higher material removal rates when rough-grinding gray cast iron substrates—outperforming traditional alumina wheels by several times. Although coarse-grained processing yields higher surface roughness, its significantly reduced machining cycles and lower tool consumption make it the preferred solution for high-volume production.

From precision micron-level to high-efficiency millimeter-level applications, the selection of CBN abrasive grain size is always centered around the machining objective. This rational matching based on material properties and process requirements not only drives technological advancements in superhard abrasives but also provides critical support for enhancing precision and optimizing efficiency in modern manufacturing.