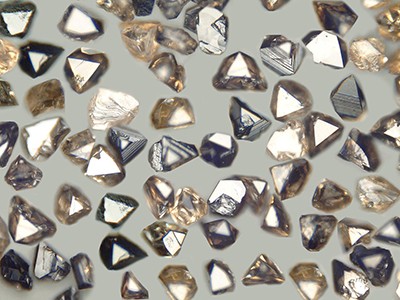

Hexagonal boron nitride (h-BN) is known as “white graphite” because of its hexagonal layered structure, soft texture and white appearance similar to graphite. As a two-dimensional material with a single atomic layer, its boron and nitrogen atoms are arranged in a hexagonal shape, which gives it high thermal stability (withstanding 1000°C in air), high thermal conductivity, electrical insulation (wide bandgap of about 5.5 eV), strong ultraviolet luminescence, and resistance to chemical corrosion, and its neutron absorption capability expands its functionality.

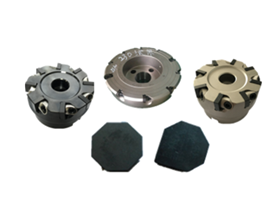

Under the trend of miniaturization and high speed of electronic devices, h-BN has become a key material for chip heat dissipation by virtue of its excellent thermal conductivity, which can effectively avoid the performance degradation caused by local overheating; its high-temperature lubrication resistance is excellent in the wide temperature range of -200℃ to 900℃ and vacuum environment, especially suitable for graphite due to the conductive or reactive limitations of the scene. Through hot pressing process, h-BN can prepare high-temperature insulating ceramics, which are widely used in electronic packaging, sputtering targets, seals and other fields, and compounded with titanium diboride is used in the metal coating industry, and compounded with silicon nitride is made into low-loss ceramic radomes, which are used in the aerospace and nuclear industry. As a thermally conductive plastic filler, h-BN's insulating and thermally conductive properties make it an ideal material for highly integrated electronic products such as LED lamps and aerospace devices, which significantly improves the performance and reliability of the equipment. In the precision manufacturing field, h-BN is used as a mold release agent to improve the surface quality of metal/ceramic castings and reduce mold losses, and its anti-sticking properties help release molds and reduce surface defects in glass processing.

In addition, h-BN coatings are stable under extreme temperatures and corrosive environments, making them suitable for high-temperature protection of spacecraft, automobile engines and metallurgical equipment. In the cosmetic field, h-BN at 3%-30% enhances makeup adhesion and slip while providing natural whitening effects. The high boron content also gives h-BN excellent neutron absorption properties, making polyurethane-based coatings both nuclear protective and decorative. With its unique physicochemical properties, hexagonal boron nitride shows irreplaceable value in the fields of microelectronics, aerospace, new energy and daily chemicals, etc. With the breakthrough of material modification technology, its functionalized application prospect will continue to expand, and it will become one of the key materials to promote the development of high-end manufacturing and emerging industries.