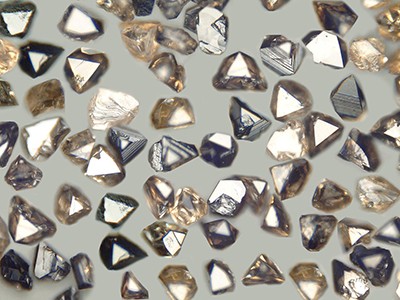

Cubic boron nitride single crystal (CBN) is a synthetic superhard material that does not exist in nature. Its unique crystal structure is formed by nitrogen and boron atoms tightly bonded through sp³ hybridization, creating a dense structure similar to diamond. This gives it high density and ultra-high hardness, with a Mohs hardness of 9.7, second only to diamond, making it an important member of the superhard materials family.

In the field of grinding, CBN single crystals have become a “powerful tool” in the grinding industry due to their outstanding performance. It can efficiently handle the grinding requirements of difficult-to-machine materials such as black metals. When combined with binders such as metal, resin, electroplating, and ceramic to form grinding wheels, it not only exhibits outstanding grinding performance but also possesses excellent self-sharpening properties. In high-speed steel roller cutter tooth grinding operations, CBN grinding wheels can precisely maintain tool shape, with grinding efficiency improved by over 30% compared to traditional alumina grinding wheels; When applied to camshaft processing, the working speed can easily exceed 160 m/s, significantly reducing the processing cycle. Additionally, in the grinding of components such as drill bits, milling cutters, reamers, and automotive drive shafts, it demonstrates advantages of high precision and long service life.

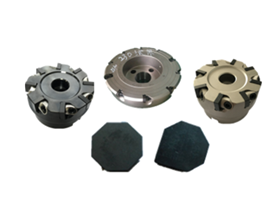

CBN single crystals also hold significant potential in the field of cutting tool materials. Micron-sized CBN single crystal micropowder is sintered at high temperature and pressure to fuse with the binder phase, forming polycrystalline cubic boron nitride (PCBN), which is widely used in metal processing. PCBN tools combine high hardness, wear resistance, high toughness, chemical inertness, and high-temperature red hardness, enabling stable machining of high-hardness, wear-resistant materials such as hard steel, tool steel, and cast iron in high-temperature environments. In automotive manufacturing, it can directly machine hardened transmission gears, achieving a surface roughness of Ra0.4μm or below, with tool life exceeding 50 times that of carbide tools; In the mold industry, it is used to process cold-working mold cavities with a hardness of HRC55 or higher, enabling the “machining instead of grinding” process, with a 40% increase in processing efficiency; when machining bearings, hard-surface turning of bearing rings can ensure IT5-grade dimensional accuracy, significantly reducing subsequent grinding processes.

In the electronics field, CBN single crystals are also gaining prominence. As a wide-bandgap semiconductor material, it has a bandgap width of 6.4 eV, an intrinsic absorption limit of approximately 193 nm, and exhibits high thermal conductivity, high resistivity, strong resistance to oxidation and high-energy particle radiation, as well as excellent thermal and chemical stability, making it an ideal material for vacuum ultraviolet photodetectors. Although currently synthesized CBN crystals have issues such as small size and high levels of impurities and defects, researchers are actively developing high-performance MSM-type vacuum ultraviolet photodetectors based on CBN, which are expected to play an important role in fields such as national defense, astronomy, and aerospace in the future.