Hexagonal boron nitride (h-BN) powder, with its unique properties, has become a key material for evaporation boats in the vacuum coating field. With a melting point of 3000°C and an extremely low thermal expansion coefficient, it can effectively withstand the thermal shock of rapid cooling and heating during the coating process, preventing boat cracking and ensuring stability in high-temperature environments. Additionally, h-BN exhibits outstanding chemical inertness, barely reacting with active metal melts such as aluminum and copper, thereby effectively preventing corrosion-induced contamination of the coating layer and ensuring coating purity.

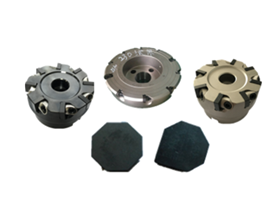

In terms of thermal conductivity, h-BN has an in-plane thermal conductivity exceeding 250 W/(m·K), enabling uniform heat distribution and significantly enhancing coating efficiency and film uniformity. Nitrogen Boron Technology removes impurities through a continuous calcination process to ensure stable powder performance. Precise particle size control (D50 adjustable between 4-20 μm) enables an optimized structure where coarse particles form a skeletal support and fine particles fill gaps, resulting in high density and bending strength after thermal pressing of the evaporation boat. Additionally, its plate-like morphology design forms a horizontally oriented thermal conductivity network, further enhancing thermal conductivity performance.

The application of h-BN not only improves the performance and service life of evaporation boats but also reduces production costs, driving the vacuum coating industry toward precision and efficiency. From electronics and semiconductors to the new energy sector, h-BN powder is helping to overcome technical bottlenecks in high-temperature, high-frequency, and high-precision applications, becoming an indispensable core material in advanced ceramic manufacturing.

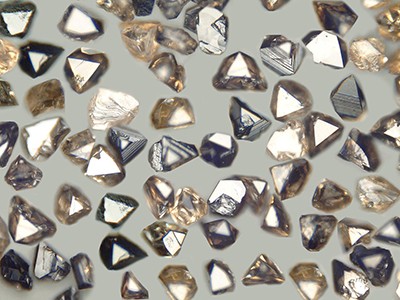

Nitrogen Boron Technology specializes in h-BN production technology, equipped with advanced continuous calcination facilities. Our products feature high purity, stable performance, and excellent consistency, backed by robust bulk supply capabilities and cost advantages. Currently, four product specifications are available: PBN700 (purity ≥99.5%), PBN500 (purity >99%), PBN300 (purity >98%), and PBN100 (purity >97%). The crystalline grain size ranges from 1 to 5 μm, and the powder particle size D50 can be adjusted between 4 μm and 20 μm. These products have been successfully applied in various industries such as thermal conductive fillers, lubricants, cubic boron nitride synthesis, and boron nitride ceramics, providing reliable support for downstream technological upgrades.