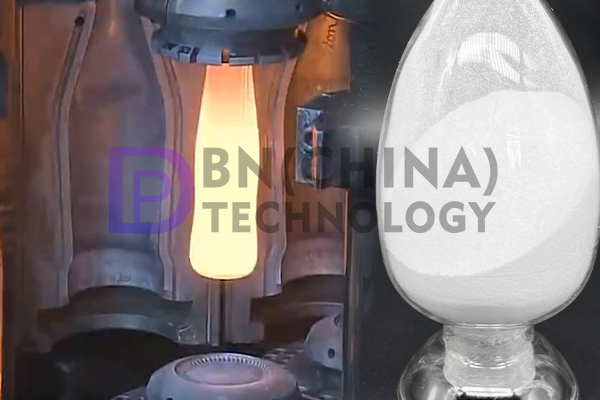

In the manufacturing field of high-temperature industry, faced with hot metal melt and hot glass melt, hexagonal boron nitride (h-BN) has become an important material indispensable for mold release technology due to its excellent layer structure and chemical stability. This compound, known as “white graphite”, is ideal for high-temperature mold releases because of its interlayer slip properties, which give it superb lubricity and stable performance even at extreme temperatures.

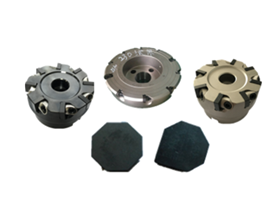

In the metal casting industry, the application value of hexagonal boron nitride is particularly obvious. In the gravity casting of aluminum and special metals, for example, boron nitride-based mold release agents such as BN-C80 are tightly adhered to the mold surface to form an isolation barrier, blocking direct contact between the molten metal and the mold. This not only significantly reduces the risk of mold sticking, but also extends the life of the mold, while improving the surface finish and dimensional accuracy of the castings. In the more demanding hot isostatic pressing process of powder metallurgy, boron nitride composite release agents build a strong pressure-resistant coating on the surface of graphite molds, resisting the puncture of metal powder under high pressure and high temperature to ensure that the products are released intact.

Glass manufacturing is also deeply dependent on its excellent performance. In the production of glass bottles, jars or curved glass, boron nitride mold release agents replace traditional grease, significantly improving mold release efficiency and production continuity. It prevents the glass from bonding to the mold, reduces product surface imperfections and improves the working environment. In high-temperature sintering process, the boron nitride coating on the graphite sintering plate effectively blocks the migration of carbon to the sintered parts and solves the problem of inter-material reaction bonding.

The core advantages of hexagonal boron nitride as a high-temperature mold release tool are: its amazing high-temperature resistance and strong chemical inertness to molten metal and glass; excellent chemical isolation, not being wetted by most of the molten material, blocking the harmful reaction; long-lasting lubrication characteristics, low coefficient of friction and high-temperature self-lubrication to reduce mold wear; user-friendly, can be made into a water-based or oil-based emulsion, by simple spraying to form a uniform film and dry quickly. It can be made into water-based or oil-based emulsion.

It can be seen that the application of hexagonal boron nitride in metal, glass, ceramics and other high-temperature molding fields not only optimizes the mold release effect and improves the product quality, but also provides a solid guarantee for the green manufacturing with its environmentally friendly and long-life characteristics. As a reliable choice for high-temperature mold release, it guards the precision boundaries of modern industry in high-temperature flames.