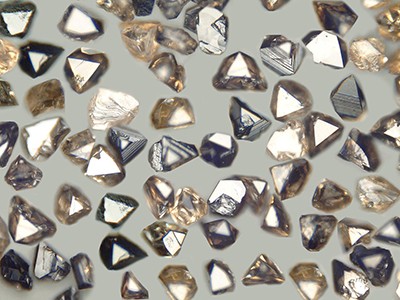

In coalfield geological exploration and coalbed methane development, diamond drill bits are critical components for ensuring efficient drilling. They are primarily categorized into two types: standard flat-faced bits and spherical-faced bits, each suited for different operational conditions.

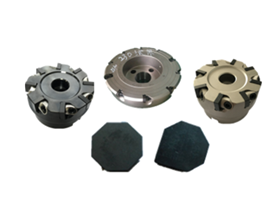

Standard flat teeth feature a straight cutting edge at the tip, with a simple and robust structure. Their advantages lie in mature manufacturing processes and relatively low costs. They perform stably in drilling medium-hard coal seams and relatively homogeneous rock layers, providing reliable drilling efficiency. Their wide contact surface ensures they can withstand significant drilling pressure in stable strata, with smooth cutting, uniform wear, and an ideal service life. However, in complex coal layers with frequent alternations between soft and hard strata or containing gangue, the straight cutting surface of flat teeth may experience significant impact loads when encountering hard objects, potentially causing tooth body fractures or abnormal stepped wear, which can impair drilling efficiency and shorten service life.

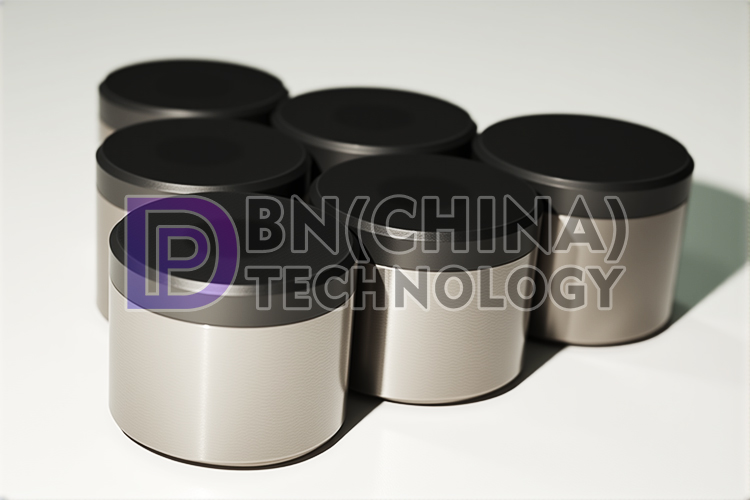

Spherical teeth are named for their end design, which features a spherical crown-shaped surface. This unique geometric shape is their core advantage: the spherical structure effectively converts drilling pressure into point loads on the rock, significantly enhancing their ability to break through hard interlayers or traverse interfaces with abrupt changes in hardness. The curved surface design provides some pressure relief and deflection space when contacting hard objects, effectively suppressing impact and protecting the tooth body. Especially in complex, unstable coal layers with large changes in drilling angle, containing a large number of hard inclusions or gravel, spherical teeth demonstrate greater adaptability and impact resistance, effectively reducing the risk of drill bit jamming and maintaining drilling continuity. Their curved surface wear is also relatively more uniform. Of course, their manufacturing costs are generally higher than those of planar teeth.

Therefore, in terms of application selection: Ordinary planar teeth, with their cost-effectiveness and stability, are the preferred choice for drilling homogeneous medium-hard coal seams, intact sandstone, or mudstone in relatively stable formations. Spherical teeth, with their superior impact resistance and adaptability to complex formations, are the preferred tool for challenging conditions such as alternating soft and hard layers, highly abrasive interlayers, fractured zones, and gravel layers, particularly for directional drilling or deep hole operations with high requirements for drill bit lifespan.

Actual selection should comprehensively consider specific coal seam hardness, abrasiveness, homogeneity, interlayered rock distribution, and drilling parameters. Understanding the structural characteristics and applicable scenarios of these two types of diamond drill bits is crucial for optimizing drilling efficiency and reducing costs in coalfield geological exploration and coalbed methane development.