In the field of metal casting, mold adhesion, thermal stress cracking, and difficult demolding have long been three major challenges plaguing production. Hexagonal boron nitride (h-BN) powder, with its unique physicochemical properties, is emerging as a key material to address these pain points.

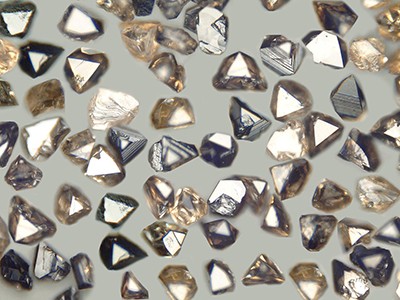

Hexagonal boron nitride powder possesses a graphite-like layered structure but exhibits greater chemical stability. Its atomic layers are bound by van der Waals forces, forming a lubricating surface with an exceptionally low friction coefficient ranging from 0.2 to 0.4. This property enables it to maintain lubricity even at high temperatures, effectively reducing direct contact between molten metal and the mold. When molten aluminum alloy is injected into molds at 660-750°C, the h-BN powder coating on the mold surface forms a barrier layer. This prevents reactions between the molten metal and the mold substrate that would otherwise generate intermetallic compounds, significantly reducing mold release resistance.

Regarding high-temperature resistance, h-BN powder demonstrates unique advantages. In an inert atmosphere, it withstands temperatures up to 2500°C, and remains stable at 1000°C in air. This property makes it particularly suitable for high-temperature casting scenarios. For instance, during precision casting of titanium alloys, mold surface temperatures often exceed 1500°C. While conventional release agents tend to decompose and fail under such conditions, h-BN powder maintains its lubricity consistently. Its low thermal expansion coefficient also effectively mitigates thermal stresses induced by temperature fluctuations in molds, preventing cracks in high-temperature zones like gates.

Chemical inertness is another core advantage of h-BN powder. This material exhibits exceptional stability against acids, alkalis, and molten metals, showing negligible reaction with common casting metals such as aluminum, magnesium, and copper. In aluminum alloy casting, traditional graphite coatings are prone to wetting by molten aluminum, leading to mold corrosion. In contrast, h-BN powder forms a dense protective layer that prevents molten metal penetration. This property also makes it suitable for complex chemical environments, such as alloy casting involving corrosive elements like sulfur and chlorine.

Regarding demolding performance, h-BN powder exhibits zero residue characteristics. Traditional silicone-based release agents often form an oily film on castings, affecting subsequent processing; graphite-based materials may leave black marks. At high temperatures, h-BN powder decomposes into nitrogen gas and boron oxide, leaving no solid residues. This maintains extremely low surface roughness on castings, making it particularly suitable for high-precision casting applications like optical lenses and aerospace components.

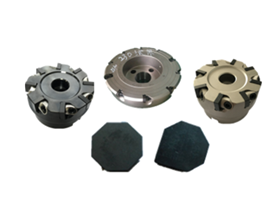

In practical applications, h-BN powder can be applied via spraying, blending, or plasma spraying. In automotive wheel casting, molds coated with h-BN composites exhibit significantly extended service life and greatly improved demolding efficiency. For thin-walled components, h-BN nano-suspension release agents substantially increase yield rates. These case studies validate h-BN powder's remarkable effectiveness in enhancing casting quality and reducing production costs.